Our services at a glance

Serialised coating expertise

Steyr Automotive offers a comprehensive portfolio of painting services for plastic and metal parts as well as carbon (CFRP) parts. Our highly automated facilities and experienced specialists guarantee the highest quality for customers in Austria, Europe and beyond – from series production to special painting. In addition, we offer our customers pre-assembly work, including just-in-sequence logistics supply to assembly plants, if required.

Our customer segments:

- (Commercial) vehicle manufacturers

- Agricultural and construction machinery

- Defence & special vehicles

- Industrial component manufacturing

modern industrial painting

Paint in figures

As contract painters, we offer our customers:

+800

active colours

40 %

less solvent thanks to modern distillation

3.000.000

Plastic parts per year in capacity

~50

coating robots in operation

Materials

- Plastic

- Aluminium

- Sheet metal

- Composite materials

- Carbon fibre (CFRP)

Coating methods

- Solvent-based process

- Water-based process

- Military painting process

Processes

- Cathodic dip coating

- Automatic seam sealing

- Pre-treatment

When requirements are particularly high

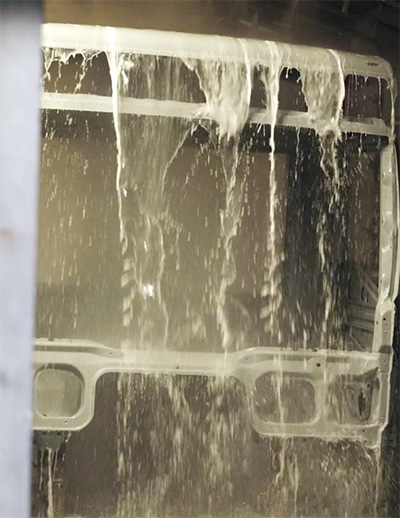

Cathodic dip coating in Upper Austria

For customer segments with particularly high demands on quality and corrosion protection, Steyr Automotive offers cathodic dip coating of metal parts. This electrochemical process, in which metal parts are coated with an aqueous, electrically conductive paint in a dip bath, guarantees an even and robust coating even on complex components.

These include, for example:

- Agricultural machinery

- Forestry equipment

- Mining equipment

- Complex components in mechanical engineering